Revolutionizing Manufacturing: The Power of Digital Twins

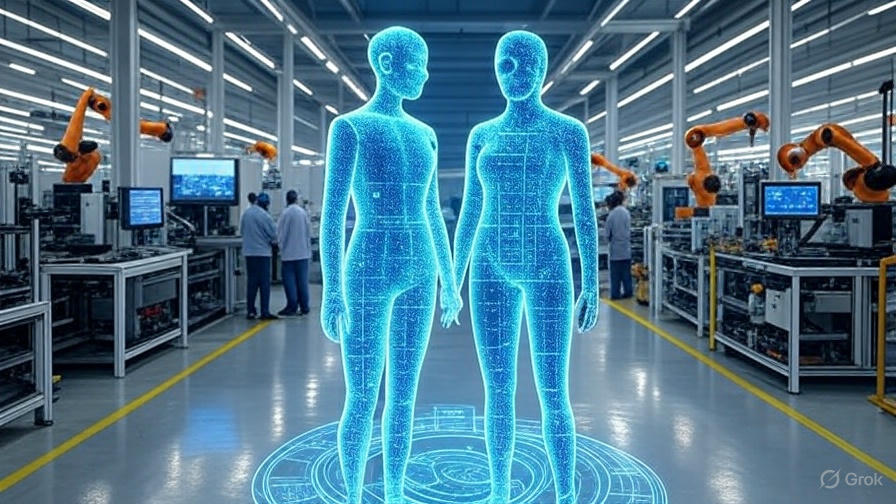

Digital twins are transforming manufacturing, bridging the physical and digital worlds to optimize processes, reduce costs, and drive innovation. A digital twin is a virtual replica of a physical asset, process, or system, updated in real-time with data from sensors, IoT devices, and other sources. In manufacturing, this technology is reshaping how factories operate, from design to production to maintenance. Let’s explore how digital twins are being used in manufacturing processes and why they’re a game-changer.

1. Streamlining Product Design and Development

Digital twins enable manufacturers to simulate and test products virtually before physical prototypes are built. By creating a digital replica of a product, engineers can analyze its performance under various conditions, identify design flaws, and optimize functionality.

-

Example: Automotive manufacturers like BMW use digital twins to simulate vehicle designs, testing aerodynamics, crash scenarios, and material durability. This reduces the need for costly physical prototypes and accelerates time-to-market.

-

Impact: According to a 2023 Deloitte report, companies using digital twins in product development can reduce design cycles by up to 30% and cut prototyping costs significantly.

2. Optimizing Production Processes

On the factory floor, digital twins of manufacturing equipment and production lines provide real-time insights into performance. By integrating data from IoT sensors, manufacturers can monitor machine health, predict failures, and optimize workflows.

-

Example: General Electric (GE) uses digital twins for its jet engine production lines. The twin monitors machine performance, detects anomalies, and schedules maintenance proactively, minimizing downtime.

-

Impact: A 2024 McKinsey study found that digital twins can improve overall equipment effectiveness (OEE) by 10-20% in smart factories.

3. Enhancing Predictive Maintenance

One of the most powerful applications of digital twins is predictive maintenance. By analyzing real-time data from a machine’s digital twin, manufacturers can predict when components are likely to fail and schedule maintenance before issues arise.

-

Example: Siemens employs digital twins in its gas turbine manufacturing plants. The twins analyze sensor data to predict wear and tear, reducing unplanned downtime by up to 15%.

-

Impact: Predictive maintenance powered by digital twins can lower maintenance costs by 10-40%, per a 2023 Gartner report, while extending equipment lifespan.

4. Improving Supply Chain Resilience

Digital twins aren’t limited to individual assets—they can model entire supply chains. By creating a virtual replica of the supply network, manufacturers can simulate disruptions, optimize logistics, and improve decision-making.

-

Example: During the 2021 global chip shortage, Intel used digital twins to simulate supply chain scenarios, identifying bottlenecks and rerouting materials to maintain production.

-

Impact: Companies leveraging digital twins for supply chain management report a 20% improvement in delivery times and a 15% reduction in logistics costs, according to a 2024 PwC study.

5. Enabling Sustainable Manufacturing

Sustainability is a growing priority, and digital twins help manufacturers reduce waste and energy consumption. By simulating processes, companies can identify inefficiencies and adopt greener practices.

-

Example: Unilever uses digital twins to optimize its packaging lines, reducing material waste by 12% and energy use by 8% across select facilities.

-

Impact: Digital twins can contribute to a 10-20% reduction in carbon emissions in manufacturing, aligning with global net-zero goals, per a 2023 World Economic Forum report.

Challenges and Future Outlook

While digital twins offer immense potential, challenges remain. High initial costs, data integration complexities, and cybersecurity risks can hinder adoption. Small and medium-sized enterprises (SMEs), in particular, may struggle with the upfront investment. However, advancements in cloud computing and AI are making digital twins more accessible.

Looking ahead, the integration of digital twins with AI and machine learning will unlock even greater capabilities. For instance, AI-powered twins could autonomously optimize production schedules or predict market demand. By 2030, the global digital twin market in manufacturing is projected to reach $70 billion, growing at a CAGR of 38%, according to a 2024 MarketsandMarkets report.

Conclusion

Digital twins are revolutionizing manufacturing by enabling smarter design, optimizing production, enhancing maintenance, strengthening supply chains, and promoting sustainability. As technology evolves, their adoption will only accelerate, paving the way for more efficient, resilient, and innovative factories. For manufacturers, embracing digital twins isn’t just an option—it’s a competitive necessity in the Industry 4.0 era.