About Us

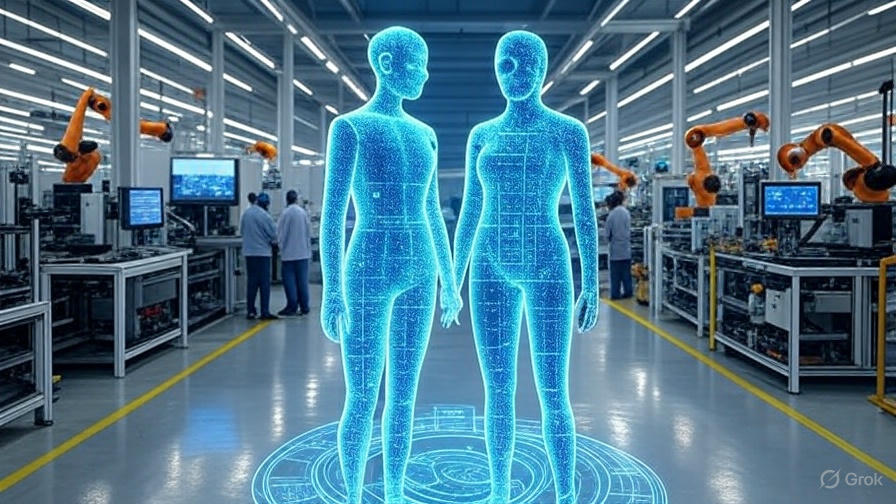

At Ingenium, we are passionate about reshaping the future of manufacturing through the power of AI and digital twin technology. As an innovative technology company, we specialise in creating AI-driven digital twin solutions that help manufacturers unlock greater efficiency, agility, and sustainability across their operations.

Our core focus is on integrating real-time data, industrial IoT, and advanced analytics to build accurate, dynamic digital replicas of physical manufacturing systems. These digital twins allow our clients to simulate, predict, and optimise their production environments—before ever touching the factory floor.

We’ve worked with manufacturers across various sectors—from automotive to food processing—to bring their operations into the era of Industry 4.0. For example, in partnership with a mid-sized automotive components manufacturer in the Midlands, we deployed a bespoke digital twin solution that linked sensor data from legacy machines with cloud-based predictive analytics. The result? A 22% reduction in unexpected downtime and a 15% boost in overall equipment effectiveness (OEE) within the first six months.

In another case, we helped a leading beverage producer digitise its bottling line using our real-time monitoring and simulation platform. By creating a live digital model of their production line, they were able to identify bottlenecks, optimise their shift scheduling, and reduce energy consumption during peak hours—supporting their sustainability targets while also increasing throughput.

What sets us apart is our ability to seamlessly combine data science, domain expertise, and user-focused design. We don’t just deliver software—we partner with our clients to understand their unique challenges and co-create solutions that fit their processes and people. Whether it’s optimising predictive maintenance schedules, reducing waste, or enabling remote diagnostics and control, we bring measurable value to the factory floor.

Sustainability is at the heart of what we do. By helping manufacturers reduce energy use, lower emissions, and maximise resource efficiency, we support the transition to greener, smarter factories. Our technology empowers teams to make proactive, data-driven decisions that benefit both the bottom line and the planet.

At Ingenium, we believe in continuous innovation, transparency, and long-term partnership. As technology evolves, so do we—always staying one step ahead so our clients can, too.

Let’s build the factory of the future—together.

Reduction in unexpected downtime

Boost in overall equipment effectiveness (OEE)